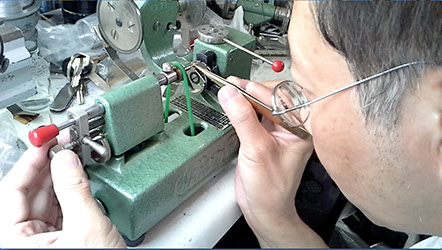

Lorch precision drill press (left) is utilized in watch factories for fine engravings on metal plates, and bridges such as Geneva patterns hat are common on hand made watches.

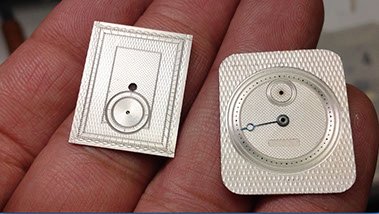

The left tool (with handle) is a crystal cutting tool. Two clamps secure a rectangular piece of crystal on its rotating platform. It has a measurement side that positions the cutting tool to match a sample, and by rotating the handle while pressing the cutting tool against a clamped piece of crystal, a round piece is cut out.

Left bottom are two sets of precision drill bits with 3.18 mm shanks.

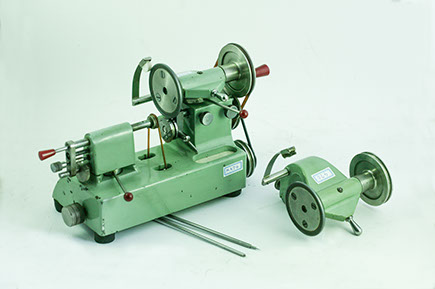

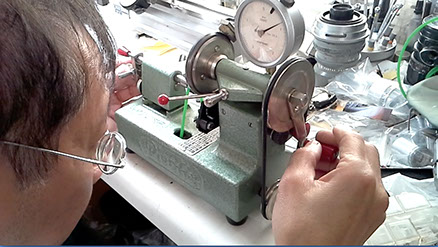

Below left is a bench top pivot grinder. If the pivot bends or breaks on a watch gear or escapement, the pivot can be straightened, but it will not be perfectly straight. The pivot grinder rotates the escapement wheel while grinding its shaft under pressure of a carbide grinding disc.

Below right, NSK air powered 65,000 rpm drilling head for micro-drilling. You can't do micro drilling with your Black & Decker because you'll need high RPM. The smaller the drill, the lower the surface speed of its circumference, and a higher RPM is needed.

Pivot Polisher

NSK 65,000 RPM Drill Head

Bergeon micro welding machine repairs broken stems from back of watch dials. Watch dials are secured via two stems welded on their back that drop into the front Mech plate. Two set screws secure the stems in place.

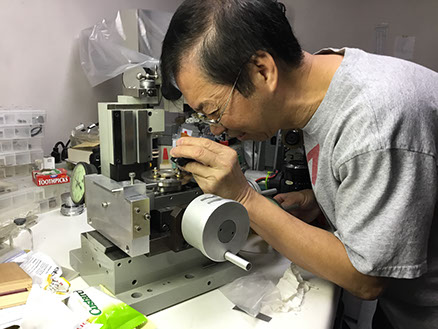

Bergeon Micro Drill Press

Here's Coung Dang, my Vietnamese watchmaker friend, teaching me how to use the pivot polisher tool. Coung is a knowledgeable craftsman.

Setting the Micro Drill for correct depth