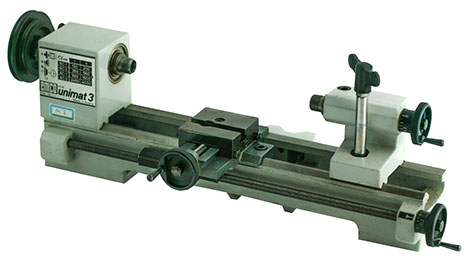

Unimat Lathe, and Mill

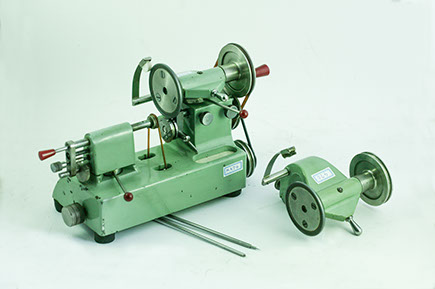

Levin Lathe, and Mill

Micro machine Tools

Measurement Tools

Making of Hasselblad Moon Camera

Please visit the Hasselblad section to see the finished camera. My recommendation is to have these machines, i.e., for polishing, and restoration. It takes a precision machinist to maintain a micromechanics museum displaying cameras, measurement tools, clocks, and watches, etc.

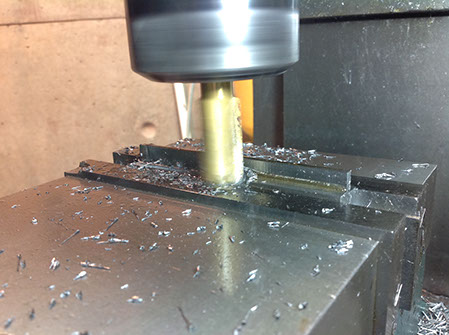

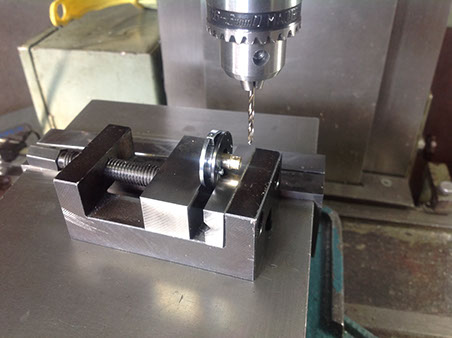

Cutting solid steel (left) and final shaping of lens focus tabs by hand. Preparing parts for powder painting in two colors matched with the camera.

Levin watchmaking lathe is utilized here to make screws, and slotting the screw head, and other precision parts required to build the camera.

Making a replica of Hasselblad Electric camera that went to the moon is not that difficult if you have the right tooling. When I visited Deutsches Museum in Munich, I saw how each section had their own maintenance department. I am not sure of their capabilities there, but I am certain they have many facilities equipped with precision machine tools to make micro mechanics parts. Cameras need maintenance, and if today's museums don't have proper skills, they could say good bye to many of their artifacts. All the light seal on the back door, and around the pentaprism of 35 mm cameras (Olympus OM-1, Nikon F2, Konica FS1, Canon FTb to name a few) have turned into sticky glue, or black powder if not replaced already.

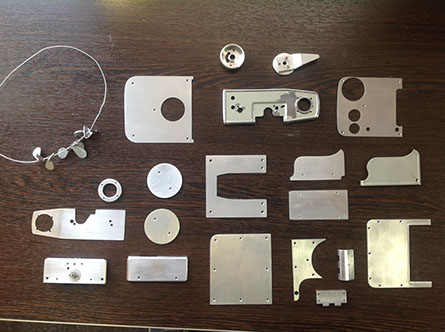

Finished Hasselblad Electric camera assembled from machined parts after matched color powder coating, anodizing, and laser engraving

Hasselblad replica was made by making measurements from actual photos. The camera was measured from many directions, comparing to the original.