Micos stages are manufactured in Eschbach, Germany with such beautiful aesthetics, and engineering design. When I visited the company (below, right) I noticed a wall on the entrance hall had the same angle you see on their stages! This kind of attitude is taken seriously in European design.

Making of PI - Micos stages

PI - Micos building in Eschbach, Germany

Inside of PI - Micos factory (above) illustrates Germany's philosophy in design that high tech products are made in high tech environments.

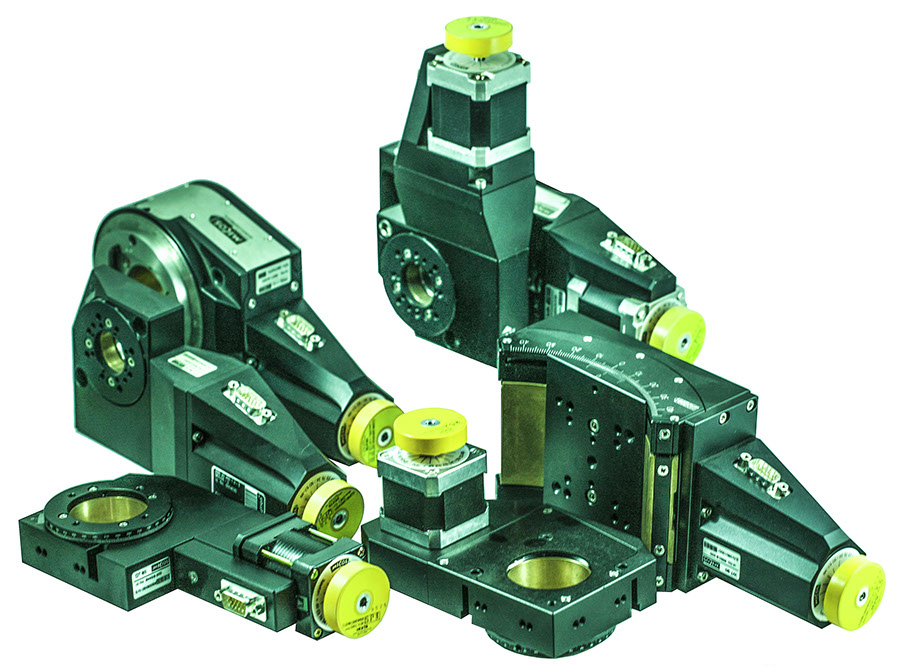

A large travel X-Y microscope stage made by Micos reveals the same characteristic yellow wheels on its motors. The yellow wheels actually contain a heavy washer floating in viscus gel. This helps the motors run faster because of the internal inertia produced inside the wheels.

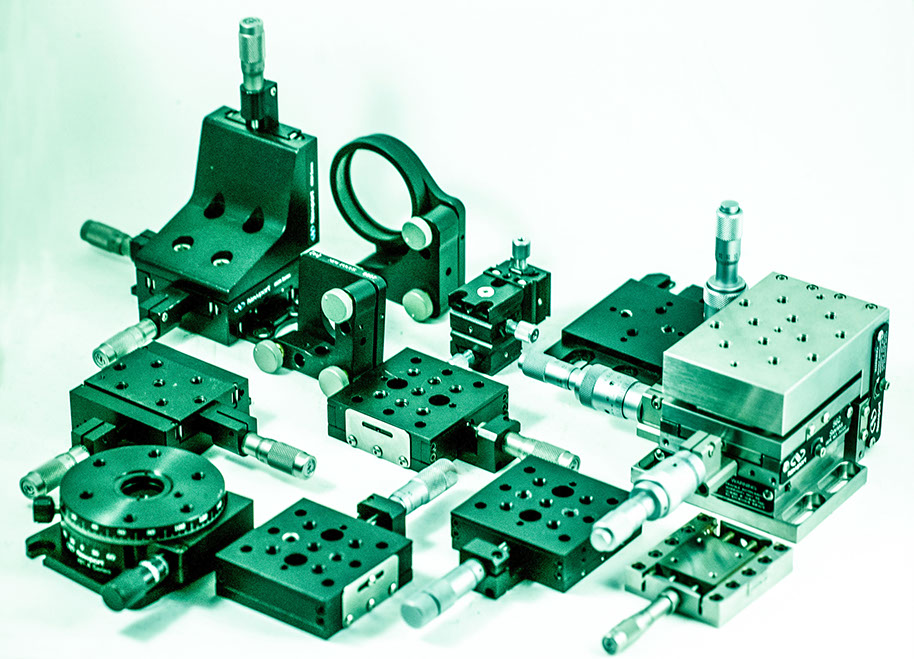

Manual Stages made by Newport, New Focus, and Klinger (France) for studying the real accuracy of linear bearing, rotational, and tilt stages..

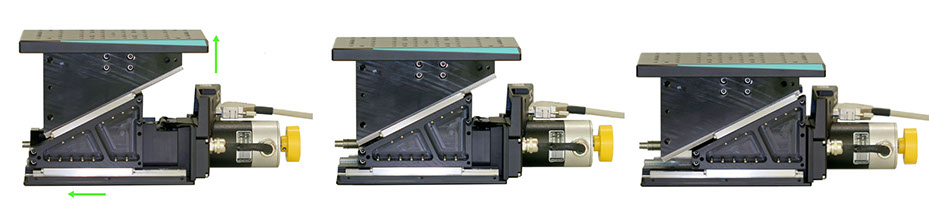

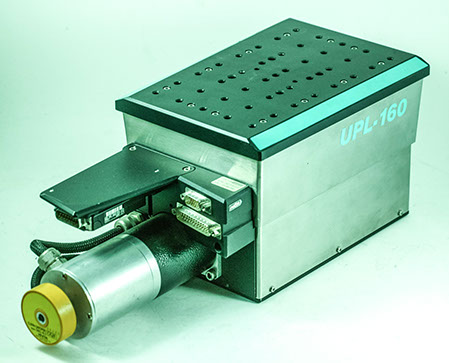

Left, Micos lift stage UPL-160 design utilizes triangular motion transfer linear bearing scheme. This stage utilizes four right-angle triangles that are connected to the top, and base plate via four linear bearing guides (above). The top, and bottom plates are additionally linked together via two vertically mounted linear bearing guides which only allow the upper plate to have a vertical motion. They are placed at the center of the stage.

Above, right, he lower triangle set is pushed in by a stepper motor, and ball screws just like a standard linear bearing stage. This causes the upper triangle set to be pushed forward but because of the two vertical linear bearings the upper triangle set is pushed up (above left).

The strength of this stage and its parallelism depends on its two vertical linear bearings, and the diagonal, and horizontal linear bearings. This is an extremely powerful stage, and it could perhaps split wood lugs. The housing is cleverly designed. You have to know what you are doing to access the inside of this stage. Height = 145 mm, Travel = 26 mm, Load Capacity = 30 Kg, Top Platform = 152 x 219 mm, Weight 8.7 Kg